What's so hard about auto racing

Sorry for my extended absence from this newsletter. Around this time last year I took on a new client: a racing team in the INDYCAR league. This kept my hands full for a while. Let me tell you about it.

The Dallara DW12 Chassis is the spec frame for INDYCAR. It weighs 1,650 pounds fully loaded, runs a 2.2 L V6 engine that pulls 700 horsepower, and when trimmed for the Speedway for the Indy 500, it's among one of the fastest and most powerful race cars on earth. Yes, faster than F1. Average lap speeds for the F1 league's Italian Grand Prix top out around 160 mph, while for oval courses INDYCAR cars are routinely averaging 220 mph.

I was brought in to help my client improve the quality and consistency of their operations. More on that in a minute.

There are five key levers that determine race performance. In order to win on race day, an INDYCAR team has to outperform on every single one of these dimensions:

- Driver performance

- Race strategy

- Pit Stops

- Engineering

- Operations

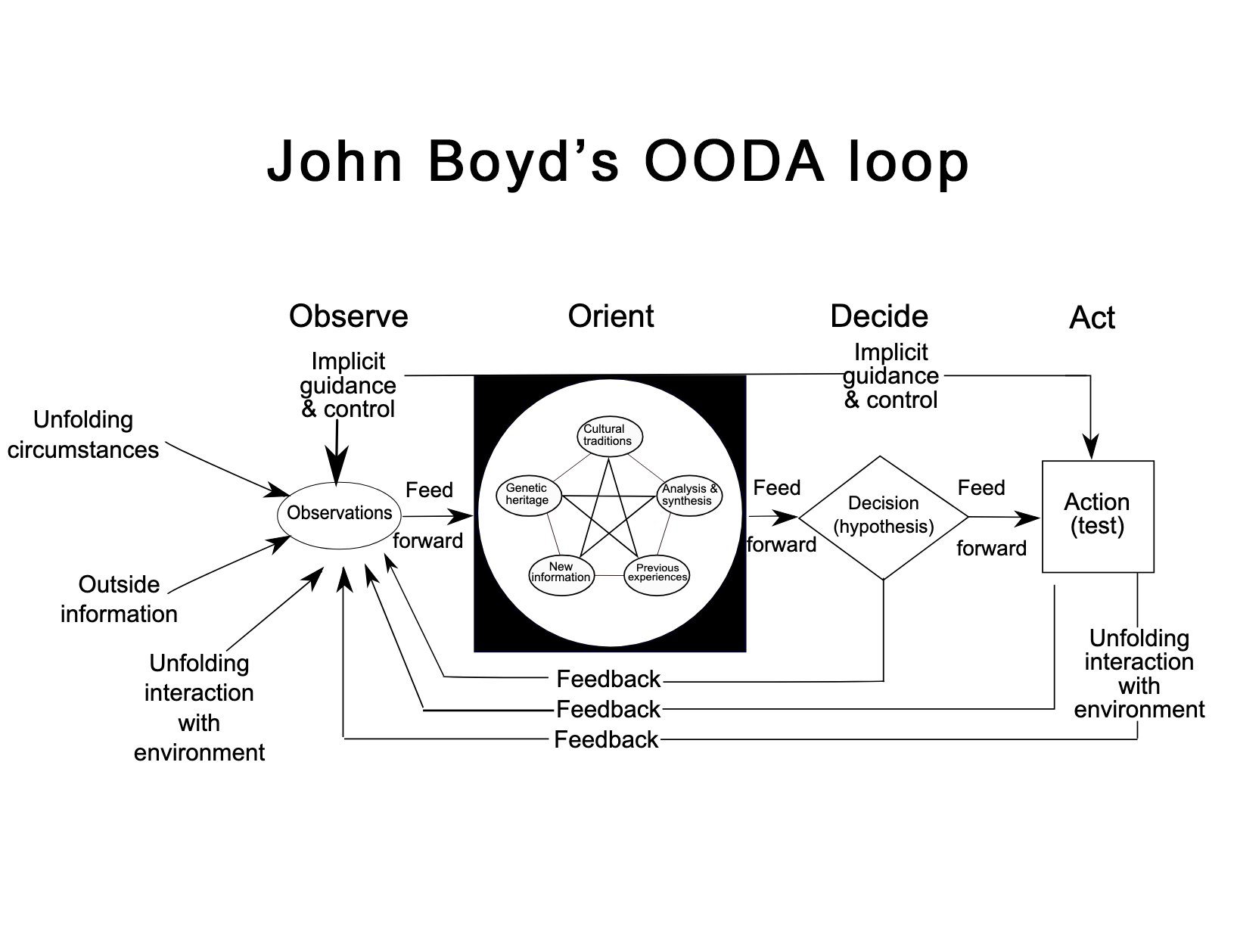

Driving a race car is a continuous series of bets. The driver has to push the car to the limits of performance while maintaining control. Push too far, and you spin out and crash. Aggressive driving eats up precious resources: tires degrade, fuel burns up, engines load with too much heat. More cautious driving saves resources, but if you go too slow, you lose. Throw tactics into the mix: attacking to gain position is riskier than defending. If you're in the lead, adversaries will continually test with feints and pass attempts. Situational awareness and split-second decision-making are paramount. This is the OODA loop at its rawest and most vital.

The heat of competition and the demands of zooming down the track at 200 mph quickly lead to driver task saturation, so the driver is supported with a Race Strategy function. Race Strategists maintain a continuous radio link with their drivers. They make decisions about when to pit, what tires to use, and what engine settings are appropriate. They enhance the driver's situational awareness with constant cues about track conditions and what cars are around them. They keep the driver mentally oriented to the race plan.

The Pit Crew changes tires and re-fuels the car. It's an insanely dangerous job. A typical race can involve 3-6 pit stops, each of which is a no-fail operation. A good pit crew can change tires, refuel, tear off plastic windscreens and make airfoil adjustments in about 6 seconds, all while rival cars are zooming through pit late mere inches from where they're working. Crashes and fires in pit lane aren't uncommon.

The Engineering Team designs the optimal setup for the car. Even though INDYCAR uses a standard chassis, the car's performance and handling can be changed by manipulating hundreds of parameters. Weight balance, ride height, aero surface angles, gearbox ratios, and suspension settings are just a few among the chief ones. The engineering team's job is really a combination of analysis and design work. Data come from wind tunnel testing, prior races, and extensive simulation. The end goal is to design an optimal configuration for the car given the type of track, weather conditions, the strengths and weaknesses of engine, and driver preference. Their work begins in the off-season but continues right up until race day as conditions change.

Supporting all this is a whole set of operational systems. Teams of mechanics disassemble the car and completely rebuild it in between each race. This is where consistency pays off, and tight coordination between engineers and mechanics is essential. This is where my work for the last few months has been focused.

Drawing on my experience with running complex no-fail operations as a former Army officer, we've prioritized a set of common-sense upgrades to improve operations quality and consistency. Because racing ops are cyclical rather than continuous, there are good parallels with military operations; teams prepare, deploy, execute, and then return to base to reset. There's a battle rhythm.

I don't want to give away all the secret sauce because of the highly competitive nature of the racing business, but I'll give you an idea of what we've been implementing. Better inventory control, standardized procedures, pre-flight checklists, and a formalized error tracking and resolution system are just some of the systems we've put in place. All of this is accomplished by sitting down with the line operators first and hearing their ideas about what to prioritize. It's my experience that within most large organizations there's already a lot of latent desire and capacity for improvement in place and so most of my engagements with teams are about unlocking, accelerating, and formalizing this capability rather than swooping in with a textbook of top-down best practices that might not be applicable.

I'm still in the middle of this engagement, but initial results are promising. The team is reporting better operational consistency, and we think this is resulting in better race performance with fewer unforced errors. Now that we have some basic systems in place, the next few months will focus on improving the rigor of our improvement project with metrics designed to measure the day-to-day quality of our operations. Unlike manufacturing, where we could easily measure things like scrap rate, cycle time, throughput, or unit cost, auto racing ops are more fluid: the inputs are complex, and the output is just "winning vs. losing." Nonetheless, we've found a set of measurable operational inputs which we're certain will result in better race performance if we can optimize them effectively. I'll let you know how it goes.

Race forward.

If you work with complex operations and are interested in improving your ops consistency and team performance, shoot me an email at rich@blackpowder.io and let's chat about it. I also provide a fractional CFO service, so if you need to upgrade your financial ops stack let's talk about that too.